253

ห้องซื้อ-ขาย-แลกเปลี่ยนของจิปาถะ / Re: GMS Interneer oil & gas equipment users in Thailand

« เมื่อ: พฤศจิกายน 09, 2021, 05:29:31 pm »

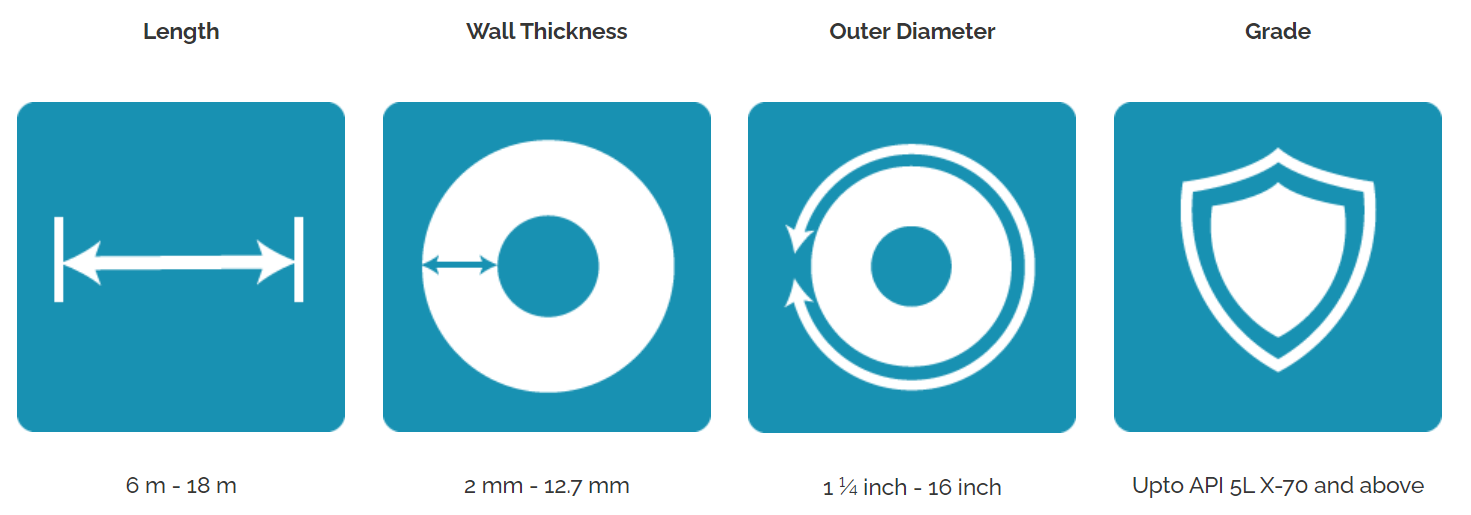

Welpsun Pipeline with Engineering Excellence

Welspun Corp Limited (WCL) is one of world’s-leading welded line pipe manufacturer, and the flagship company of the Welspun Group. Welpsun Pipeline , we believe in acquiring talent, developing skills, engaging individuals in multiple projects, and providing them with world-class experience and exposure, while keeping our core values at the crux of these activities.

We’re a team of nearly 4,000+ people across the world, focused on building a culture of ‘Engineering Excellence’in our Welpsun Pipeline

Over the last two decades, our innovative approach and, technical capabilities have helped us deliver some of the path-breaking Welpsun Pipeline projects across the world.

With over $1.2 billion of annual revenue, Welspun Corp is a true Indian multinational, operating across multiple geographies. We share a close relationship with our customers, and are the providers of choice for some of the largest players in the global oil and gas industry.

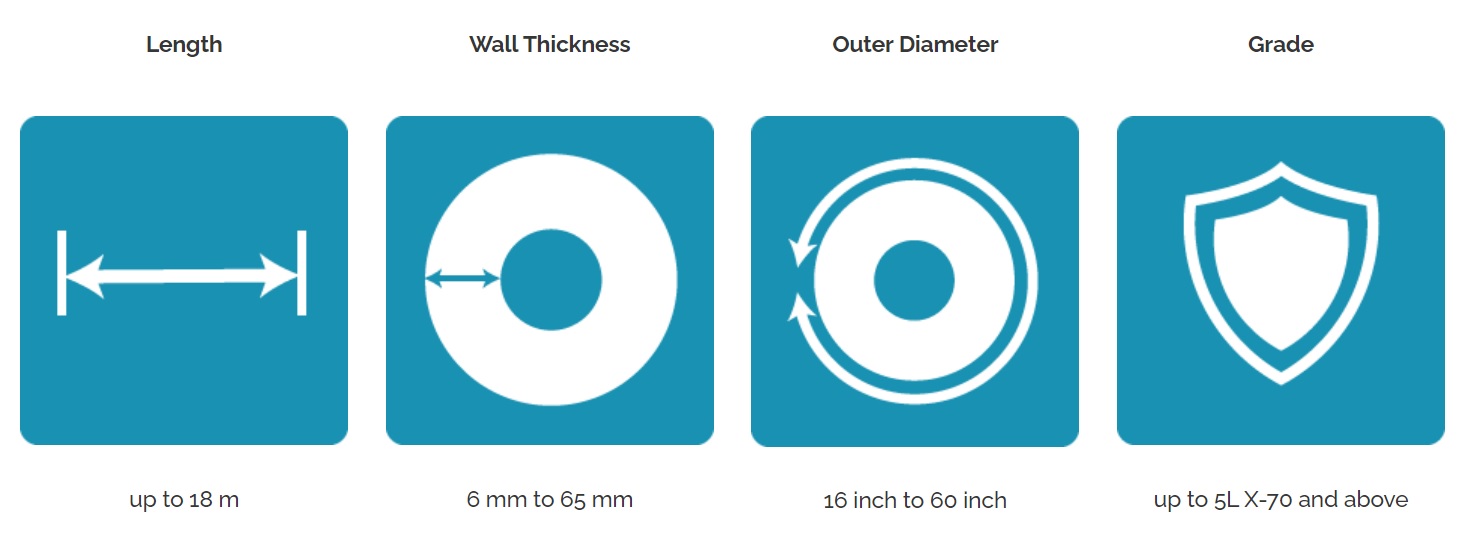

Welpsun Pipeline Capacitied and Capabilities

ERW

Technical Excellence

- 90 m long Looper Tunnel/ Accumulator with 180 meters strip length capacity

- 600 kW solid state High Frequency Welder with on-line monitoring and data recording

- 1500 kW Seam Normalizing Unit comprising 3×500 kW Induction Units

- On-line Internal Bead Scarfing with CCTV monitoring

- State-of-the-art ROTO UT System (Immersion Testing) for Weld, HAZ and Pipe Body (100% coverage)

LONGITUDINAL SUBMERGED ARC WELDED (LSAW)

Technnological Excellence

- High thickness rolling capabilities

- Auto Pipe Dimension Measurement System (APDMS)

- Online Plate UT System

- State-of the-art, high capacity, PLC governed Mechanical Expander

- High capacity (650 bar) Hydro Testing Machine

- State-of-the-art Auto UT from GE Inspection Technology (2 lines)

HELICALLY SUBMERGED ARC WELDED (H-SAW)

Award

https://www.gmsthailand.com/product/welpsun-pipeline-with-engineering-excellence

https://www.gmsthailand.com/product/welpsun-pipeline-with-engineering-excellence

Welspun Corp Limited (WCL) is one of world’s-leading welded line pipe manufacturer, and the flagship company of the Welspun Group. Welpsun Pipeline , we believe in acquiring talent, developing skills, engaging individuals in multiple projects, and providing them with world-class experience and exposure, while keeping our core values at the crux of these activities.

We’re a team of nearly 4,000+ people across the world, focused on building a culture of ‘Engineering Excellence’in our Welpsun Pipeline

Over the last two decades, our innovative approach and, technical capabilities have helped us deliver some of the path-breaking Welpsun Pipeline projects across the world.

With over $1.2 billion of annual revenue, Welspun Corp is a true Indian multinational, operating across multiple geographies. We share a close relationship with our customers, and are the providers of choice for some of the largest players in the global oil and gas industry.

Welpsun Pipeline Capacitied and Capabilities

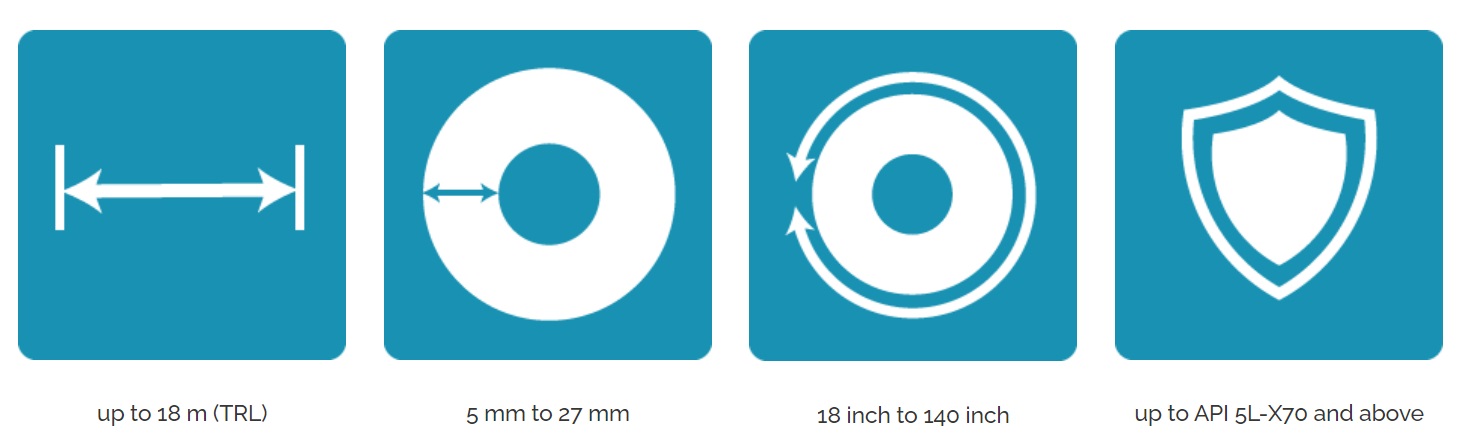

ERW

Technical Excellence

- 90 m long Looper Tunnel/ Accumulator with 180 meters strip length capacity

- 600 kW solid state High Frequency Welder with on-line monitoring and data recording

- 1500 kW Seam Normalizing Unit comprising 3×500 kW Induction Units

- On-line Internal Bead Scarfing with CCTV monitoring

- State-of-the-art ROTO UT System (Immersion Testing) for Weld, HAZ and Pipe Body (100% coverage)

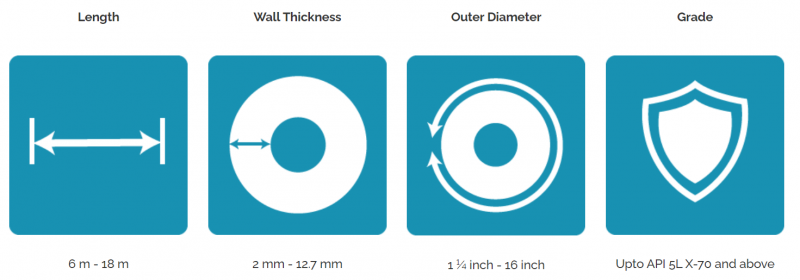

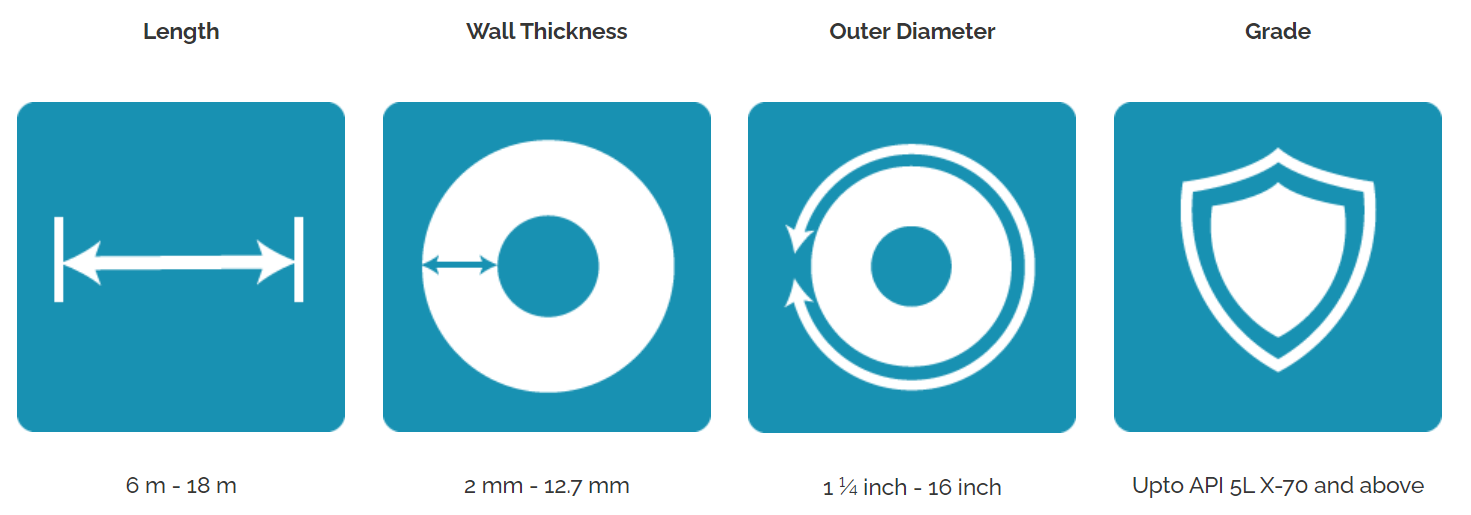

LONGITUDINAL SUBMERGED ARC WELDED (LSAW)

Dahej: 3,50,000 MTPA

Anjar: 3,50,000 MTPA

Anjar: 3,50,000 MTPA

Technnological Excellence

- High thickness rolling capabilities

- Auto Pipe Dimension Measurement System (APDMS)

- Online Plate UT System

- State-of the-art, high capacity, PLC governed Mechanical Expander

- High capacity (650 bar) Hydro Testing Machine

- State-of-the-art Auto UT from GE Inspection Technology (2 lines)

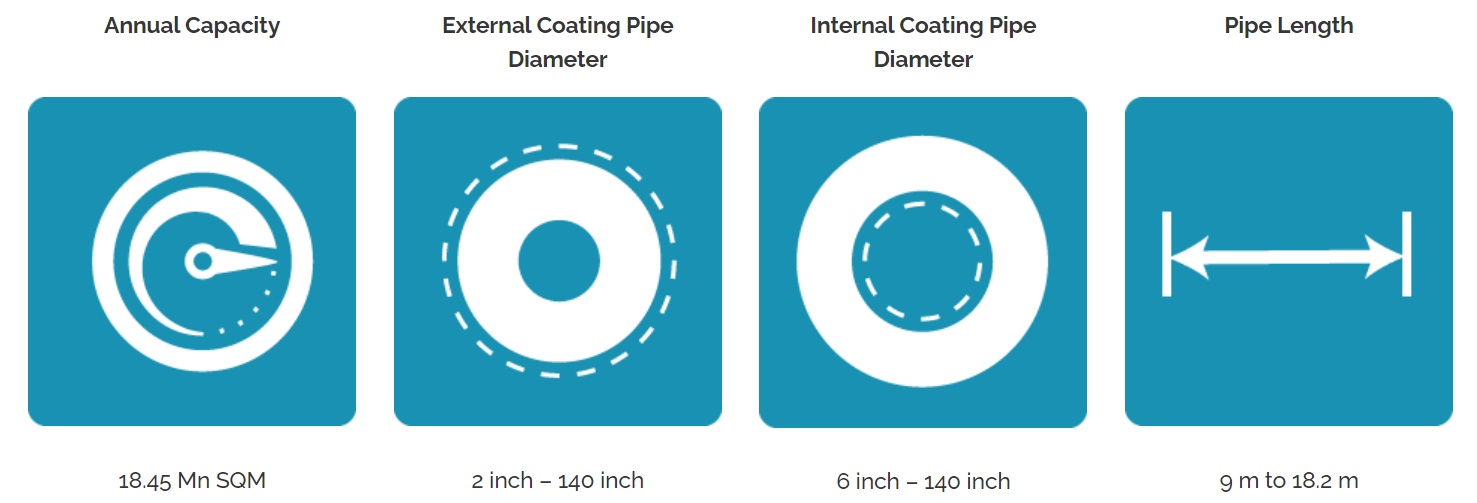

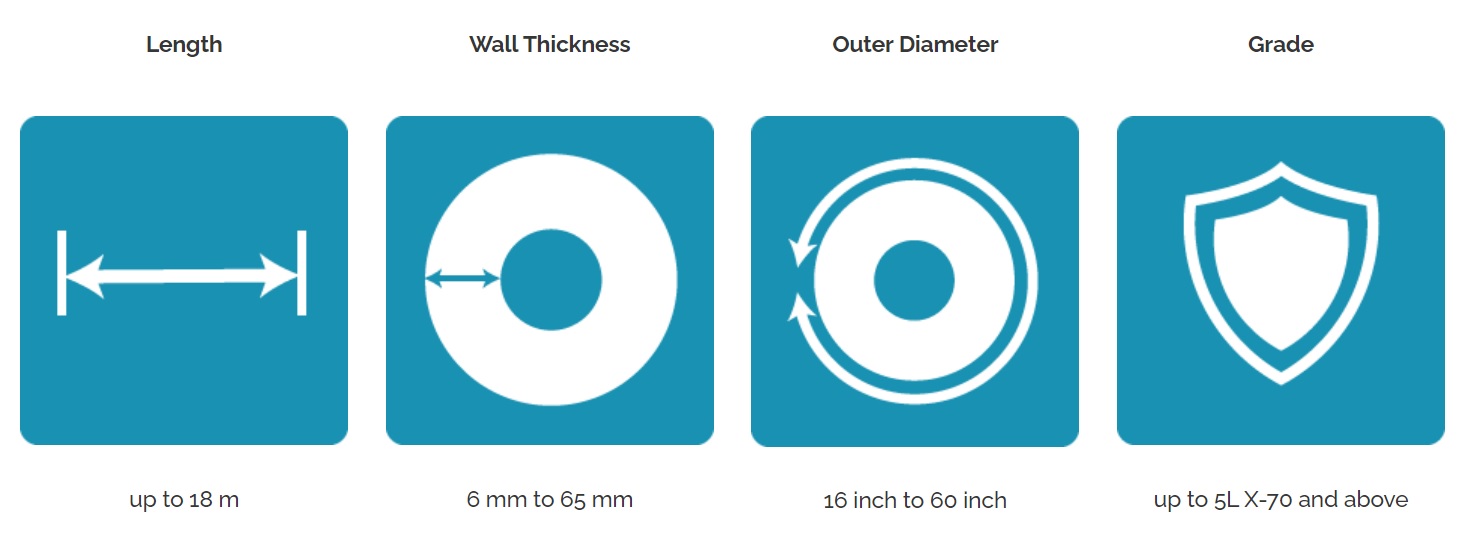

HELICALLY SUBMERGED ARC WELDED (H-SAW)

Anjar: 3,80,000 MTPA

Dahej: 50,000 MTPA

Mandya: 1,50,000 MTPA

Bhopal: 1,75,000 MTPA

Dahej: 50,000 MTPA

Mandya: 1,50,000 MTPA

Bhopal: 1,75,000 MTPA

Award